One of the crucial challenges of titanium is heat dissipation. Palmer often shares advice including all of the following tips: To realize more of the potential of those processes that do have the potential to machine titanium productively, Mr.

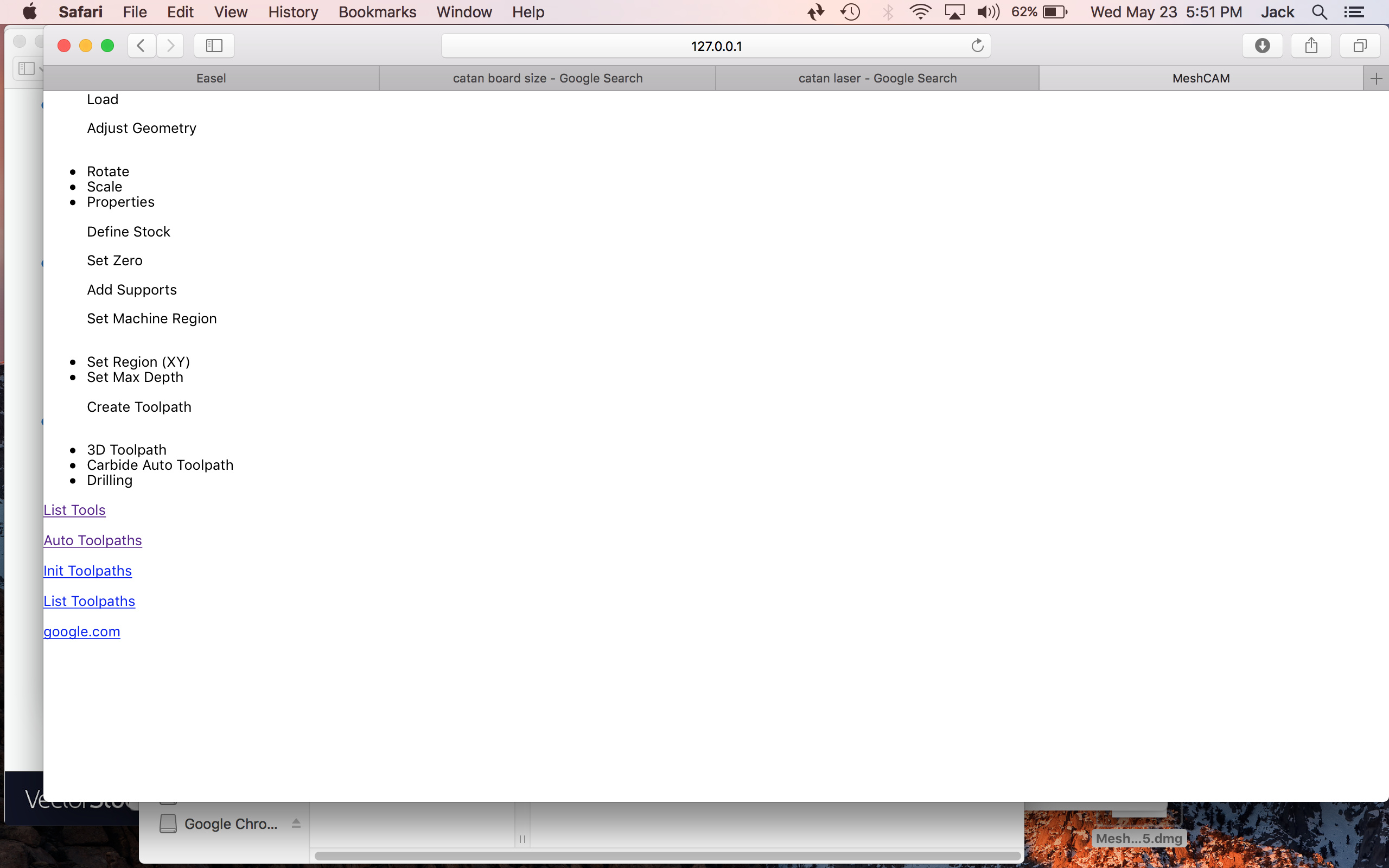

Meshcam 6 quits unexpectedly while machining depth plus#

Other important considerations include coolant pressure and volume, as well as the method of coolant delivery, plus methodology and application-the focus of this article. The tool, toolholder, spindle, column, ways, table, fixturing and workpiece are all part of that circle, and part of the needed stability. When the tool touches the workpiece, it closes a circle. He says titanium does not have to be difficult-it’s just that the entire machining process has to be considered, because any one element could impede the overall process’s effectiveness. He consults with manufacturers about methods for improving milling performance in various aerospace alloys, titanium alloys included. Many valuable techniques for machining titanium effectively are not difficult to employ, but few shops use all of the techniques that are available for milling this metal productively. John Palmer, global aerospace segment manager for cutting tool maker Stellram, says many of these shops actually have more titanium machining capacity than they realize.

10 Characteristics of a Valuable Machine Shop

0 kommentar(er)

0 kommentar(er)